Is there any danger for my vehicle’s electrical system?

No. Our product is safe for your electrical system, wires and all its electronic components. In fact, mineral oil (the base of our product) is used in Hydro-Quebec transformers to isolate electrical currents.

Can the manufacturer cancel my warranty?

No. It would be illegal in this case to cancel a warranty without proving an irrefutable cause and effect link.

How much experience does Metropolitan Rust Proofing have with EVs?

To date, we have treated more than 8,000 electric and hybrid vehicles, all makes combined.

I have read in articles that to properly treat an electric vehicle, it can take up to 3 to 4 hours of work. It is also said that it is imperative that no product be applied to the electrical module, or it could void the manufacturer’s warranty. How can you provide an effective and safe treatment in just a few minutes?

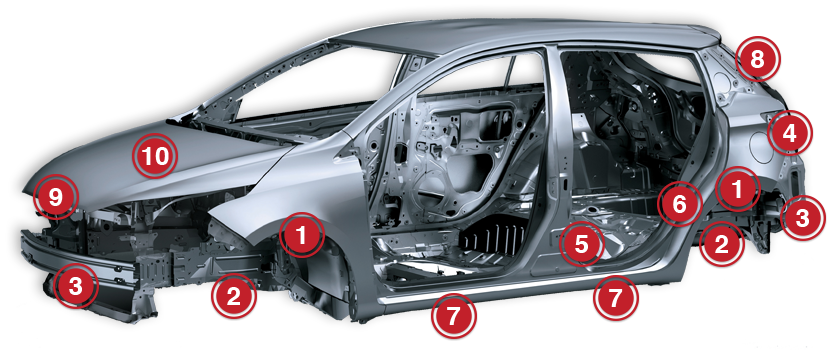

There is no rust protection sprayed on the electronic components as they are already protected from splashing water from the road. We only treat the vehicle body and it is in no way different from a standard vehicle body. Vehicles have always been designed with electronic and electrical modules, computers, fuse boxes, batteries, electric motors, parking sensors, etc. The difference between a gasoline and electric vehicle is the battery, which is protected against road hazards. The reason why our treatment can be performed quickly and efficiently is because our work skills and expertise have allowed us to do so since we have been treating electric and hybrid vehicles for over 20 years.